|

Gear Up to Electric Only New Production Line at BBAC Battery Plant for Upcoming All-Electric EQE Officially Online

|

| Source: Release Time: 2022-05-23 16:47:10 |

|

[May 23rd, Beijing] The new generation locally-produced Mercedes-Benz battery officially came off the line at the BBAC Battery Plant today, representing a major step forward in BBAC's production of pure electric products and laying a solid foundation for the mass production of a new locally-produced Mercedes-EQ model: the all-electric EQE. With the production of the new battery, BBAC gears up to “Electric Only” and steps forward to its commitment to high-quality sustainable development.

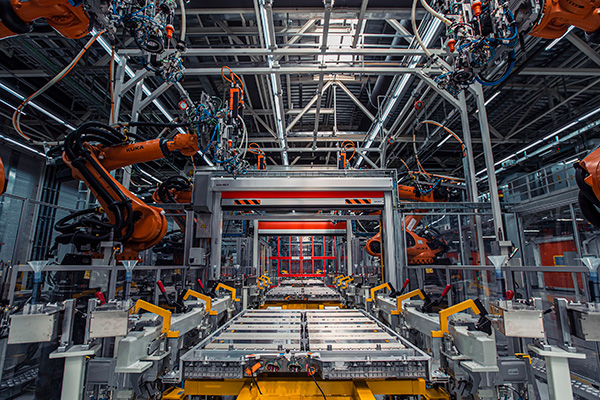

BBAC’s battery production line is tailored for the new generation of high-performance batteries, which set standards in terms of performance, efficiency and charging capacity. They also meet the high Mercedes requirements in terms of safety, durability and sustainability and are integrated into the intelligent thermal management of the EQE. The birthplace of the battery, the BBAC Battery Plant, was the first-ever Battery Plant of Mercedes-Benz Group (formerly Daimler) outside of Germany in 2019. The Mercedes-Benz global battery production network consists of factories at seven locations on three continents - in China, the US, Thailand, Poland and Germany. The plant operates with a focus on the "digital, flexible, efficient and sustainable" intelligent manufacturing concept of Mercedes-Benz using comprehensive digitalization with MO360, the digital Mercedes-Benz production ecosystem. Based on the intelligent and digital manufacturing platform, the Battery Plant is able to fully realize the production of the batteries at consistent high quality backed by intelligent maintenance. Based on big data, cloud computing and other technologies, the production line of Battery Plant carries out digital and flexible assembly, with key processes achieving 100% automation. The plant ensures intelligent production control and ensures high-quality production through analyzing, forecasting, tracing and recording the entire production process.

In order to further ensure the safety of its power batteries, the Battery Plant adheres to the safety standard of the German Association of Automobile Industry [include Chinese and/or international standard], Germany’s highest level of power battery safety requirements, ensuring consistently safe performance under extreme circumstances such as seawater immersion, fire and puncture. The Battery Plant’s production environment is optimized to remain clean and dust-free throughout the year, at constant temperature and humidity for battery production, with a full operation chain high-voltage safety management system to provide double guarantees for safe production and safe products.

To facilitate in turning the carbon neutral vision to a reality, the Battery Plant itself follows green and environmentally friendly concepts in its production and operation. By adopting a variety of energy-saving and environmental protection measures such as a plant roof skylight, intelligent energy management system and paperless production, the Battery Plant is able to significantly reduce energy consumption, effectively improve energy utilization and minimize the carbon footprint of the production process. Behind the continuous development of BBAC’s battery products is the company’s electrification transformation process based on the forward-looking strategies of its shareholders BAIC Group and Mercedes-Benz Group. As early as 2017, BBAC’s Chinese and German shareholders signed a framework agreement to lay out the development of new energy at BBAC. In the same year, the foundation of the BBAC Battery Plant was officially laid. In 2019, BBAC ushered in the first locally produced pure electric premium car, the EQC pure electric SUV, and the first battery. In 2021, the new pure electric compact SUVs EQB and EQA were successively put into operation. The new battery generation coming offline today will be carried on the all-new EQE, set to come offline in the near future. The arrival of the EQE will expand BBAC’s premium pure electric vehicle portfolio, composed of EQA, EQB, EQC and EQE, to fully cover the market segments from compact pure electric SUV, medium-sized pure electric SUV to medium-sized pure electric car, realizing a further leap in the process of electrification. Following the clear development path of electrification, BBAC is dedicated to thoroughly implementing the strategic vision of BAIC Group and Mercedes-Benz Group for electrification transformation, continuing the implementation of the MO360 digital production system, continuously refining its production process around the concept of "digital, flexible, efficient and sustainable" and accelerating the realization of "Electric Only". While providing Chinese consumers with greater choice of electric premium mobility options, BBAC aims to help China achieve its national "dual carbon" goal and promote the continuous transformation and upgrading of the Beijing and China's automobile industry. |

Contact Us

|

Legal Policy│

Privacy statement│

Friendship link│

Site map│

Hot Tel: 400-810-8880 Copyright: 2026 Beijing Benz Automotive Co., Ltd. 京ICP备05050259号-1

京公网安备 11011502003823号

京公网安备 11011502003823号